Double Disk Grinding & OD Grinding Machines

Glebar also offers a Double Disc Grinder (one of the most compact on the market), excellent for small diameter components, and OD Grinders, which excel at producing components requiring a tight concentricity specification. All of these machines are compact, powerful, and versatile, able to handle anything from Gun Barrels and Carbide Drill Blanks to Dental Drills and Ceramic Insulators.

Double Disk Grinding

Glebar’s DD-7 is one of the most compact double disc grinding machines on the market. Designed for grinding small diameter components, it accurately controls their length and perpendicularity. Applications range from printed circuit board drill blanks, carbide pins, ceramic blocks, alumina tubes, and roller bearings for the aerospace, automotive, medical, metals, and mining markets.

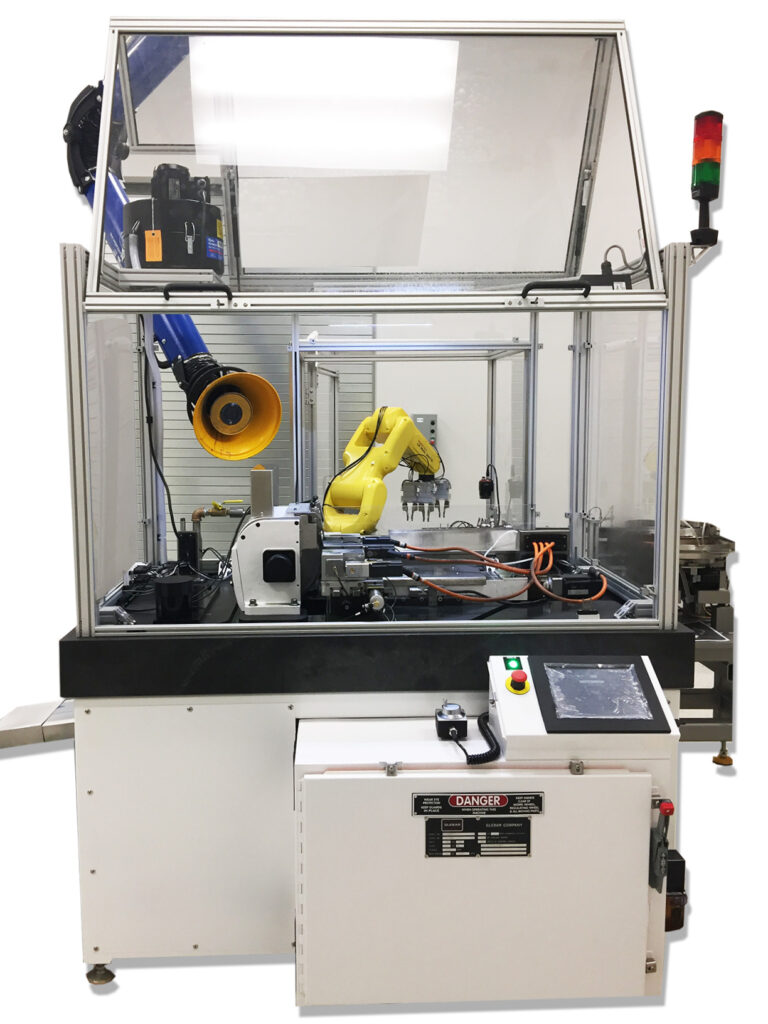

DD-7

Double Disc Grinder

The DD-7 is one of the most compact double disc grinding machines on the market. Designed for grinding small diameter components, it accurately controls their length and perpendicularity.

OD Grinding

Now offered on granite bases, Glebar’s OD Grinders can optimize production and cut cycle times up to 100%. Fully automatable, these machines can hold extremely tight concentricity specs.

PG-9DOD

OD Grinder

The PG-9DOD OD Grinder produces components requiring a tight concentricity specification. Examples include bearings, bushings, and engine components.

PG-9CRG

OD Grinder

The PG-9CRG OD Grinder shapes the diameter on parts where the diameter of the piece is concentric to the centerline of the part. The PG-9CRG manufactures things from rubber rollers for laser printers to dental drills.

FW-9D

Ferris Wheel / OD Grinder

The FW-9D Ferris Wheel / OD grinding machine forms parts concentric to the inner diameter. Typical applications of the FW-9D are car oxygen sensors, spark plugs, rubber feed rollers, and ceramic insulators.