Machine Rebuilds and Upgrades

Generate greater production efficiencies with machine rebuilds, hardware, and software upgrades.

Hardware Upgrades

Automate tasks previously performed manually reducing downtime and improving consistency during production.

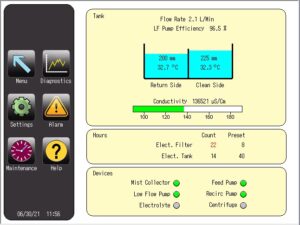

Electrolyte Tank Management System

Enhanced Sensors Reduce Reliance on Operators to Measure Electrolyte Efficiency

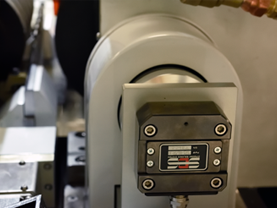

Automatic Work Wheel Balancing

Wheel balancing is crucial to achieving a good surface finish on the workpiece and is…

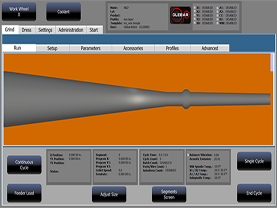

Automatic Work Wheel Dressing

Improve quality, eliminate rework, improve set up time, and ease the expertise required to properly…

CAM SXE to CAM.2 Upgrade

By trading in the CAM SXE for CAM.2, customers will have a brand new CAM…

Work Wheel Variable Speed Control Inverter

Operator gains the ability to vary the work wheel RPM optimizing cutting action.

Software Upgrades

Improving machine security and allowing off-line programming reducing downtime.

Tridex Companion Software

Converts machine data files into Windows files allowing unlimited offline storage and archiving possibilities.

OS Upgrade to Windows 10

Windows 10 is the newest OS from Microsoft, providing the latest in security protection.

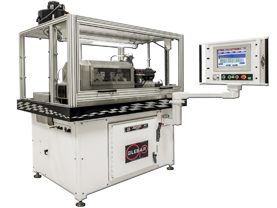

Machine Rebuilds

Glebar offers factory-rebuilt equipment. Used machines are disassembled and all worn or defective parts are replaced. The bed, ram, ram bed, and dovetails are remachined and rechromed as required. The equipment is repainted and tested to run your product.

PG-9BHD

Rebuild your PG-9BHD Form Grinding Machine to current Glebar factory specifications to ensure performance and precision.