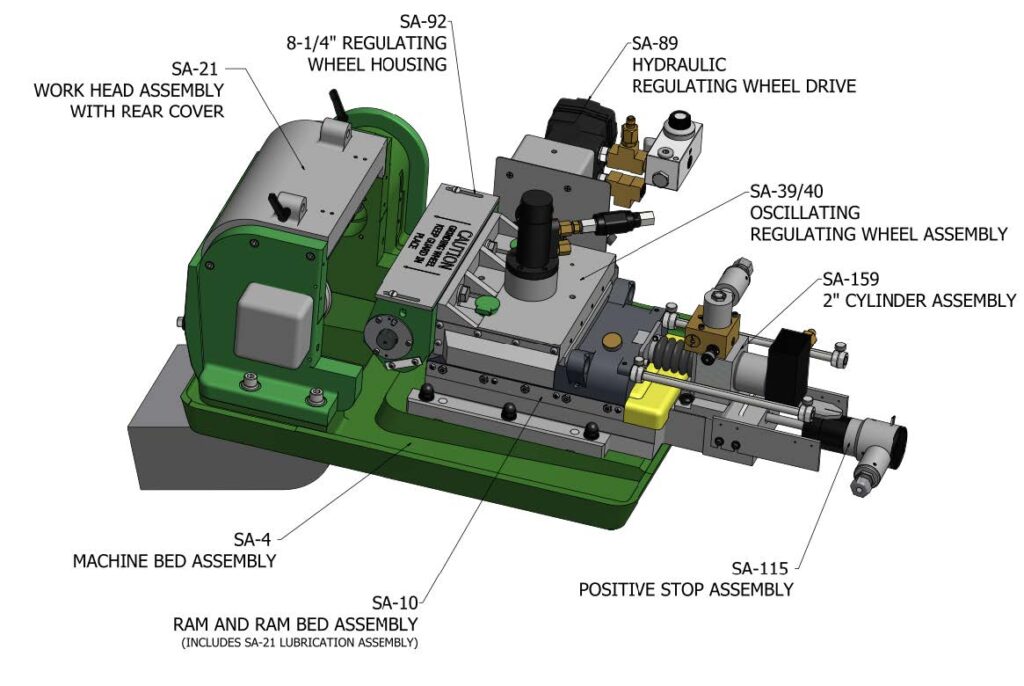

Glebar PG-9BHD Form Grinding Machine Rebuilds

Rebuild your PG-9BHD Form Grinding Machine to current Glebar factory specifications to ensure performance and precision. The top of your PG-9BHD, assembled at Glebar, is transported to your site and installed at your facility with minimal downtime.

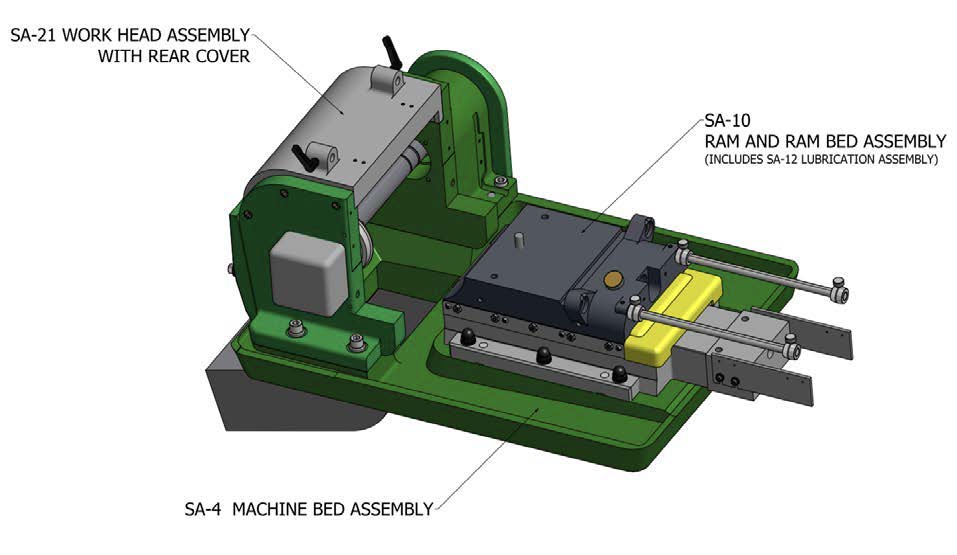

Basic Top Rebuild Includes:

- SA-4 Ground qualified machine bed casting machined to the latest revision.

- SA-21 Work head assembly including factory sourced spindles, bearings and castings machined to the latest revision.

- SA-10 Reconditioned machine slides, resurfaced dovetail ground ways, hard plated for wear resistance, Turcite coated gibs for improved contact to dovetails.

Complete Top Rebuild Includes:

SA-4 Ground qualified machine bed casting machined to the latest revision.

SA-21 Work head assembly including factory sourced spindles, bearings and castings machined to the latest revision.

SA-10 Reconditioned machine slides, resurfaced dovetail ground ways, hard plated for wear resistance, Turcite coated gibs for improved contact to dovetails.

SA-92 8-1/4 Regulating wheel housing

SA-89 Hydraulic Regulating wheel drive

SA-39/40 Oscillating Regulating wheel Assembly

SA-159 2″ Cylinder Assembly

SA-115 Positive stop assembly