Current Process

Kirschner wires, also commonly known as K-wires, are ground using a manual OD grinder.

Challenges

Low production output, as only one wire can be ground at a time. Changeover between wire diameters is time-consuming, delaying production. Grinding can leave burrs requiring secondary processes to deburr, lengthening production time.

Solution

Solution: Burr-Free Electrochemical Grinders (ECG) SG-1645 or SG-2060, ECG Point Grinding System PGS-100 from Tridex Technology, A Glebar Company

ECG provides burr-free and low-force cutting for applications with tight tolerances and heat sensitivity. The PGS-100 can be added to the SG-1645 or SG-2060 to grind points on the wires in large batches. For example, at .065″ diameter, 55 K-wires can be pointed in one batch at a cycle time of approximately 2.2 seconds each. Changeover from one diameter to another takes only 5 minutes. Changing point geometry only requires a simple CNC program edit.

For K-wires that require multiple profiles, Glebar recommends its CAM.2 Microgrinder.

Reduces machining time, increasing output.

Significantly lengthens wheel life, reducing consumables costs.

Eliminates the need to deburr, reducing production time.

Allows machining of various tips, including trocars, drills, multi-faceted, etc.

Plain or threaded parts can be produced with the same accuracy.

Capable of grinding almost any point geometry on exotic and difficult to machine materials.

The same process can be applied to grinding Steinmann Pins.

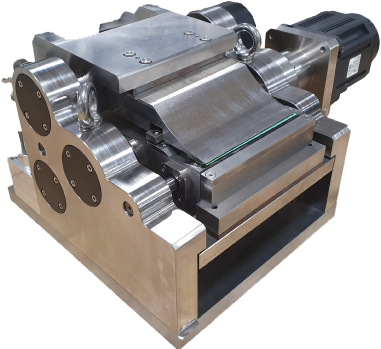

Explore | PGS-100 Burr Free ECG Point Grinding

PGS-100

When added to our Tridex SG-1645 or SG-2060 electrochemical grinders, the PGS-100 is a fully programmable pointing and material handling system to manufacture a wide variety of medical device points on tubing or solid wire, such as medical needles or K-wires, using electrochemical grinding technology (ECG).