Catheter Punching Machines and Hole Drilling

SYNEO Accu-Drill and Accu-Punch equipment solutions are advanced, space-efficient solutions for drilling burr-free holes in a wide range of single and multi-lumen tubing materials such as Polyvinyl chloride (PVC), Low-density polyethylene (LDPE), PEEK, Polytetrafluoroethylene (PTFE) and Pebax®. Accu-Drill and Accu-Punch machine solutions are heavily utilized in clean room manufacturing environments where catheter punching and hole drilling applications exist. SYNEO hole making solutions are capable of holes as small as .005”, and offer capabilities such as multi-lumen location, hole quality inspection, and drilling holes between cross-sections of braided material.

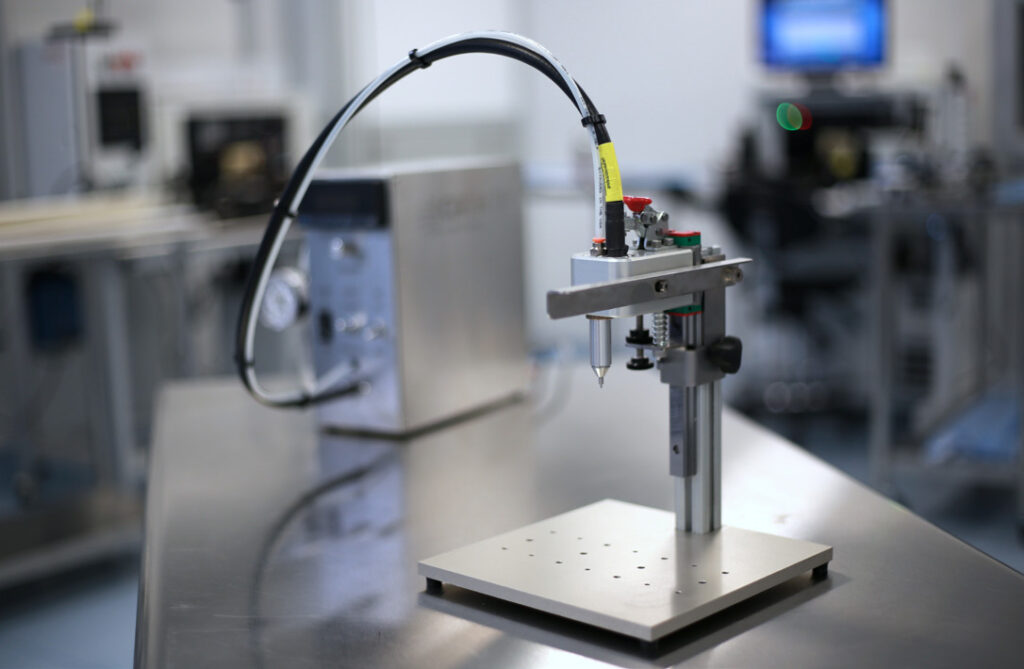

MP & MD Manual Series

The Manual Hole-Making solutions punch or drill precision holes in a variety of extruded tubing and injection molded applications.

SP & SD Automated Series

The Automated Catheter Hole Making solutions are powerful and safe solutions to hole making needs of various shapes and sizes.

DC Integrated Series

SYNEO’s Automated Catheter Drill and Cut systems allow engineers to produce finished, drilled and precision cut-to-length catheter components in a continuous and fully automated manufacturing process.

Cathtip 400 Series

The 400 Series is a precision hole drilling machine that delivers results to the highest industry hole quality standards.

Cathtip Flex-Drill

Flex-Drill by CATHTIP is the most flexible, cost-effective option for hole forming in catheter prototypes and early development applications.