Automatic Work Wheel Balancing

Current Process

Wheel balancing is crucial to achieving a good surface finish on the workpiece and is critical to the spindle bearing life. A technician balances the wheel using an offline, static system manually moving weights. The process is time-consuming, taking 30 to 45 minutes, delaying setup and production. The results are varied and not repeatable.

Challenge

Significantly reduce setup time, changeover time, and the variability of results driven by manual wheel balancing.

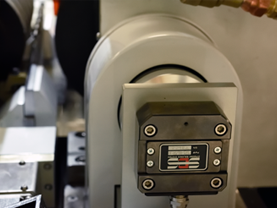

Solution: Automatic Work Wheel Balancing System. Available on Glebar’s TF-9DHD, GT-9AC, and GT-610 machines.

An automated solution where the spindle is dynamically balanced through controls in the HMI.

Upgradeable Machines

GT-610

Infeed/Thrufeed Centerless Grinding Machines

Competing designs require a much larger footprint, with wheels so large and heavy a crane is required to change them. The compact GT-610 offers high horsepower, high rigidity and superior…

Learn More

Request A Quote

GT-9AC

Micro Grinding Machines

Traditional guidewire centerless grinders use sensors to detect the wire position and trigger diameter changes, limiting the number of tapers the system can produce. Since the GT-9AC has no sensors,…

TF-9DHD

Micro Grinding Machines

Simple to operate machine with the operator in mind. Reduced setups are a result of a thoughtful design of the machine. Independent top and bottom slide controls, simple work rest…