GT-610 CNC: Infeed/Thrufeed Precision CNC Centerless Grinder

The Glebar GT-610 CNC Infeed / Throughfeed Precision Centerless Grinder is the complete “lights-out” solution for applications where a high degree of automation, data gathering, and gauging feedback is required. The fully automated system is capable of grinding and gauging multiple components per cycle. The GT-610 CNC excels in high production or frequent changeover operations with the assurance of automatic size compensation and 100% inspection. Challenging components such as arthroscopic shavers, bone drill blanks, small powdered hard metal components, aerospace fasteners, transmission bushings, and more can be easily processed.

Key Features

- Grinds multiple parts per cycle.

- Full turnkey automation integration available including feeders, robots, pick/place gantry, gauging, cleaning, and sorting assemblies.

- High-production, lights-out grinding capability.

- Independent upper and lower slide positioning.

- Ease of changeover and set up for short production runs.

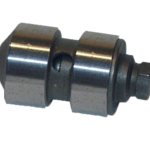

- Super high rigidity roller guides with 0.1-micron scale feedback on the ram bed and CNC Work Wheel dresser.

- Standard Twin Grip Spindle.

- Automatic wheel balancing and acoustic emissions systems.

- Automatic CNC work wheel and regulating wheel dressing.

- A single operator can change the work wheel in less than 15 minutes.

- Available variable frequency drive on the work wheel spindle increases wheel surface feet when running super abrasives such as vitrified CBN.

- Patented motorized work rest blade adjusts the lateral position of parts.

- Auto dress feature is programmable to redress the wheel after grinding a set number of parts.

- Intuitive touch screen HMI allows an unskilled operator to run multiple high-precision machines simultaneously.

- EtherCAT® connection for remote access or remote technical support.

- Glebar P4K Gauging System available to feed diameter measurements to the control system for automatic size compensation.

Specifications

- Work Wheel Diameter: 10” (254mm) or 12” (305mm)

- Work Wheel Width: 8.625” (219mm)

- Work Wheel RPM: 500-2,500

- Work Wheel Power: 15HP (11kW)

- Regulating Wheel Diameter: 6” (152mm)

- Regulating Wheel Power: 2HP (1.5kW)

- Regulating Wheel RPM: 10 – 200

- Roundness: better than .00004” (1.02microns)

- Grinding Diameter Capacity: Min 0.002” (0.05mm) – Max 2.0” (50.8mm)

- Machine Weight: 8,100 lbs (with mineral cast base)

- Diameter Resolution: better than .00005” (1.27 microns)

- Upper Slide Resolution: 0.1μm (0.000004”)

- Lower Slide Resolution: 0.1μm (0.000004”)

- CNC Dresser X Resolution: 0.1μm (0.000004”)

- CNC Dresser Y Resolution: 0.1μm (0.000004”)

- Power: 480VAC, 60Hz, 50A

- Air: 40CFM @ 80PSI

- Machine Footprint: 136” x 85” x 92” (345 x 216 x 234cm)