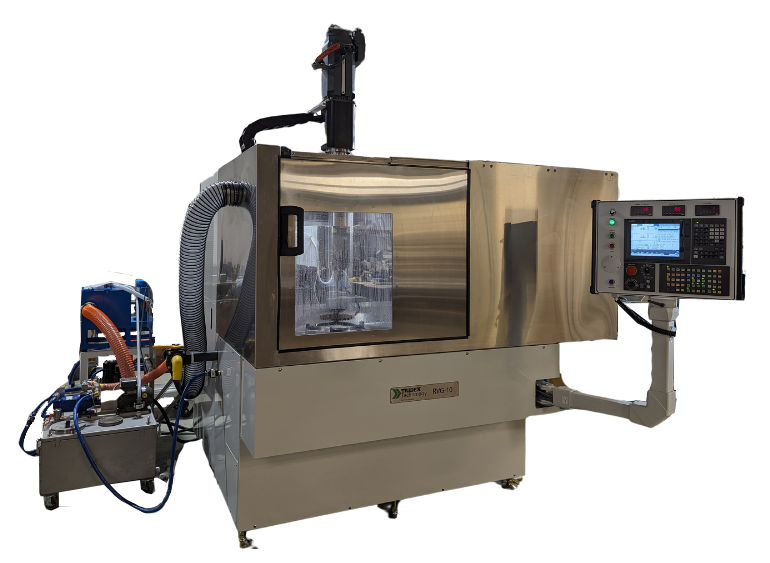

Tridex RVG-10 Electrochemical Rotary Vertical Grinder

New Product!

The Tridex RVG-10 Electrochemical Rotary Vertical Grinder is specifically designed for grinding the inside and outside of stepped honeycomb diameters of aircraft engine components. Engineered with heavy-duty cast iron components, precision preloaded linear guides and ball screws, and a comprehensive Mitsubishi M80 CNC system, it guarantees a reliable and high-performance operation. The RVG-10 delivers burr-free grinds ensuring consistency and eliminating the need for deburring and other secondary operations.

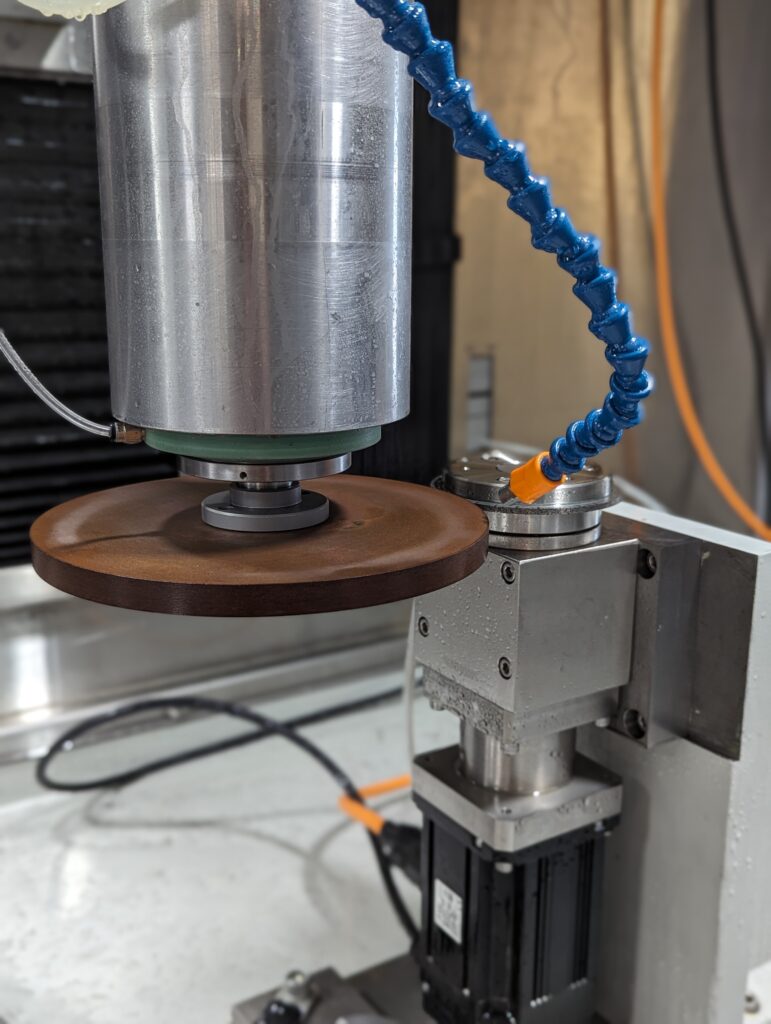

High-precision vertical spindle ensures fast, accurate grinds.

Key Features

- Completely burr-free grinds eliminate the need for deburring and other secondary operations.

- High-precision vertical spindle ensures fast, accurate grinds.

- Easy setup and operation using Mitsubishi M80 CNC with color screen.

- Full access stainless splash guard and stainless electrolyte tank.

- All vital components are located outside the wet area and are protected from electrolyte and grit.

- Remote diagnostics capability simplifies troubleshooting and maintenance.

- Servo-driven rotary table with dual mode (spindle or CNC C-Axis).

Specifications

- Spindle nose: 1” (25mm)

- Spindle Motor: Servo motor, 5.5kW, 5,000 RPM max

- Rotary table: NC table with full servo control, 4 RPM max

- Table diameter: 39.37” (1,000mm)

- Travel (X-axis, left-right): 27.55” (700mm)

- Distance to table center (MIN): -0.78” (-20mm) (overlap)

- Distance to table center (MAX): 26.77” (680mm)

- Travel (Y-axis, front-back): None

- Travel (Z-axis, up-down): 11.22” (285mm)

- Clearance above table top: 0.98” to 12.20” (25 to 310mm), to the spindle tip

- Min. wheel diameter: 1.25” (31.75mm)

- Max. wheel diameter: 8” (203.20mm)

- Power: 480 Volts 3 Phase 60Hz (380V 50Hz available)

- Air: 75 PSI (5.0 Bar)

- X and Z Axes Positioning Accuracy: .0002”(0.005mm)

- Machine Weight: 15,433lbs (7,000kg)