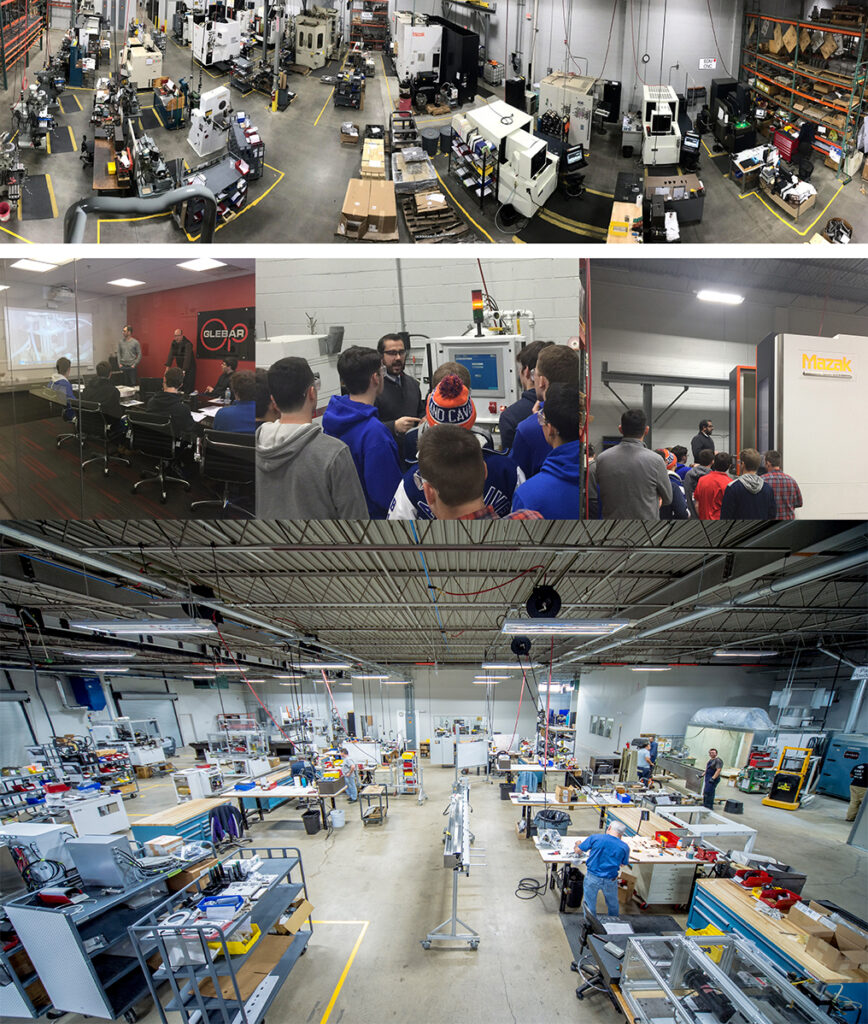

Glebar hosted high school students from Pearl River High School (NY) for an exclusive VIP tour of Glebar’s Ramsey, NJ, manufacturing facility. The students were exposed to all the steps involved in designing, manufacturing, and assembling a custom precision centerless grinding solution.

The group’s day began in the executive conference room. They were shown a case study of a fully automated cell grinding automotive spring cups (view video presentation). The machine was a fully automated GT-610 Thrufeed Centerless Grinding System, which was featured in a recent Modern Machine Shop article. The system can auto-grind the components at a rate of 2 per second with zero defects.

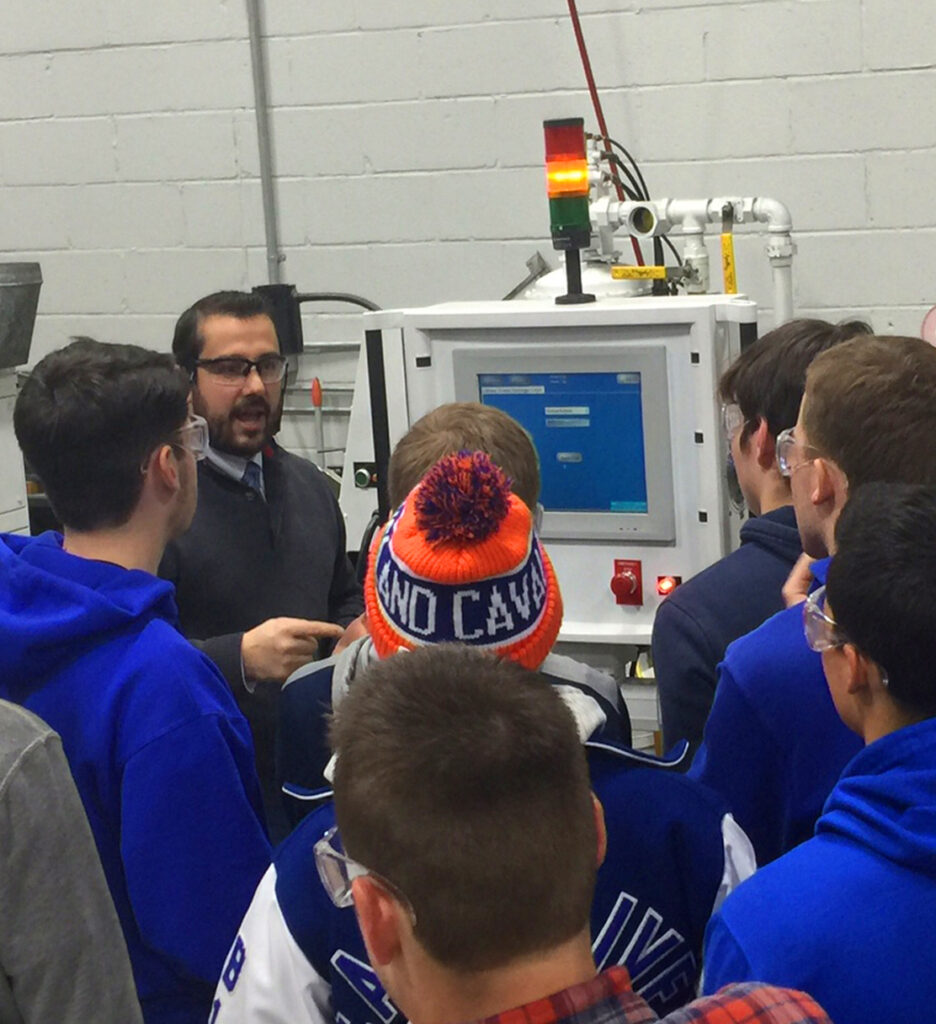

At the conclusion of the presentation, the students were taken onto the factory floor where they went on a multi-step journey of what happens once a machine order is placed. From Research and Development and Wheel Forming, to CNC Turning and Assembly, the students’ visited virtually every stop in a new machine’s manufacturing cycle.

Mark Scanel states, “It was very exciting to see such a high level of interest in our manufacturing process. These students were engaged and came with a genuine curiosity towards our company. We greatly look forward to having them return and hosting other students in the near future.”